I didn't find the manual yet ( dana) but I got another from Standard Gear as I need to replace the one in my 95... the factory pinion didn't agree with my wife's driving when I had the supercharger on that GC's engine,,,

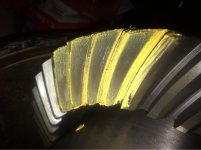

they compound should be thinned with gear oil to a thin paste and you should add only enough to squeeze out, not paint the whole tooth. when it squeezes the mark will be bare metal outlined yellow your first try or two will most likely be spent locating the contact point, not actually checking the pattern. And remember the location isn't as critical as the type of pattern on your Drive side, as it will move when you adjust for coast. its how the two patterns both look that matters more than the positioning on its own. It is extremely rare that they both match up location wise. and if you get them to, I have a couple cases of New Glaris Spotted Cow in the refrigerator...