bugleboy

New member

Updated April 29, 2005 Michelin has showcased a potentially disruptive technology with significant ramifications for the future for mobility: an airless, integrated tyre and wheel combination dubbed the TWEEL (i.e. Tyre/WhEEL) . The Tweel promises performance levels beyond those possible with conventional pneumatic technology. The first commercial applications of the Tweel will be in lower-speed, lower-weight vehicles such as the iBOT mobility device and Segway's Concept Centaur. Designed by Segway-inventor Dean Kamen, the iBOT mobility device has the ability to climb stairs and navigate uneven terrain, offering mobility freedom impossible with traditional wheelchairs. Additionally, Segway's Concept Centaur, a prototype that applies self-balancing technology to a four-wheel device, has also been equipped with Tweel to increase its performance potential.

View all

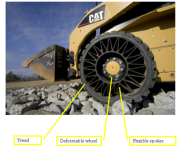

Beyond these first real-world applications, Michelin has additional projects for Tweel on construction skidsteers and a variety of military vehicles.

Historically Significant

"Major revolutions in mobility may come along only once in a hundred years," said Terry Gettys, president of Michelin Americas Research and Development Center in Greenville, S.C. "But a new century has dawned and Tweel has proven its potential to transform mobility. Tweel enables us to reach levels of performance that quite simply aren't possible with today's conventional pneumatic technology."

The most intriguing application may be Michelin's early prototype Tweel fitment for passenger cars. The mobility company released video of promising Tweel performance on an Audi A4.

"The Tweel automotive application, as demonstrated on the Audi, is definitely a concept, a stretch application with strong future potential," said Gettys.

"Our concentration is to enter the market with lower-speed, lower-weight Tweel applications. What we learn from our early successes will be applied to Tweel fitments for passenger cars and beyond."

Benefits of the Tweel

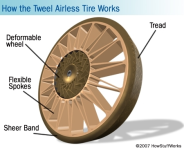

The heart of Tweel innovation is its deceptively simple looking hub and spoke design that replaces the need for air pressure while delivering performance previously only available from pneumatic tires.

The flexible spokes are fused with a flexible wheel that deforms to absorb shock and rebound with ease. Without the air needed by conventional tires, Tweel still delivers pneumatic-like performance in weight-carrying capacity, ride comfort, and the ability to "envelope" road hazards.

Michelin has also found that it can tune Tweel performances independently of each other, which is a significant change from conventional tires. This means that vertical stiffness (which primarily affects ride comfort) and lateral stiffness (which affects handling and cornering) can both be optimised, pushing the performance envelope in these applications and enabling new performances not possible for current inflated tires.

The Tweel prototype, demonstrated on the Audi A4, is within five percent of the rolling resistance and mass levels of current pneumatic tires. That translates to within one percent of the fuel economy of the OE fitment.

Additionally, Michelin has increased the lateral stiffness by a factor of five, making the prototype unusually responsive in its handling.

Future of Tweel Technology

For Michelin, Tweel is a long-term vision that represents the next step in a long path of industry-changing innovations. Fifty years ago, Michelin invented the radial tyre and there is no question that radial tyre technology will continue as the standard for a long time to come. Michelin continues to advance the performance of the radial tyre in areas such as rolling resistance, wear life and grip.

In the short-term, the lessons learned from Tweel research are being applied to improve those conventional tyre performances. In the future, Tweel may reinvent the way that vehicles move. Checking tyre pressure, fixing flats, highway blow-outs and balancing between traction and comfort could all fade into memory.

http://www.gizmag.com/go/3603/

View all

Beyond these first real-world applications, Michelin has additional projects for Tweel on construction skidsteers and a variety of military vehicles.

Historically Significant

"Major revolutions in mobility may come along only once in a hundred years," said Terry Gettys, president of Michelin Americas Research and Development Center in Greenville, S.C. "But a new century has dawned and Tweel has proven its potential to transform mobility. Tweel enables us to reach levels of performance that quite simply aren't possible with today's conventional pneumatic technology."

The most intriguing application may be Michelin's early prototype Tweel fitment for passenger cars. The mobility company released video of promising Tweel performance on an Audi A4.

"The Tweel automotive application, as demonstrated on the Audi, is definitely a concept, a stretch application with strong future potential," said Gettys.

"Our concentration is to enter the market with lower-speed, lower-weight Tweel applications. What we learn from our early successes will be applied to Tweel fitments for passenger cars and beyond."

Benefits of the Tweel

The heart of Tweel innovation is its deceptively simple looking hub and spoke design that replaces the need for air pressure while delivering performance previously only available from pneumatic tires.

The flexible spokes are fused with a flexible wheel that deforms to absorb shock and rebound with ease. Without the air needed by conventional tires, Tweel still delivers pneumatic-like performance in weight-carrying capacity, ride comfort, and the ability to "envelope" road hazards.

Michelin has also found that it can tune Tweel performances independently of each other, which is a significant change from conventional tires. This means that vertical stiffness (which primarily affects ride comfort) and lateral stiffness (which affects handling and cornering) can both be optimised, pushing the performance envelope in these applications and enabling new performances not possible for current inflated tires.

The Tweel prototype, demonstrated on the Audi A4, is within five percent of the rolling resistance and mass levels of current pneumatic tires. That translates to within one percent of the fuel economy of the OE fitment.

Additionally, Michelin has increased the lateral stiffness by a factor of five, making the prototype unusually responsive in its handling.

Future of Tweel Technology

For Michelin, Tweel is a long-term vision that represents the next step in a long path of industry-changing innovations. Fifty years ago, Michelin invented the radial tyre and there is no question that radial tyre technology will continue as the standard for a long time to come. Michelin continues to advance the performance of the radial tyre in areas such as rolling resistance, wear life and grip.

In the short-term, the lessons learned from Tweel research are being applied to improve those conventional tyre performances. In the future, Tweel may reinvent the way that vehicles move. Checking tyre pressure, fixing flats, highway blow-outs and balancing between traction and comfort could all fade into memory.

http://www.gizmag.com/go/3603/