Horray, no "hey how much" questions..

JK guys, you all need to start somewhere.

Well.. I am in the last stages of stretching teh wheel base in my 94 YJ to 106", that's moving the front axle forward about 5.5" and pulling the rear back about 5.5"

On the last trail ride I went on a couple weeks ago, I ran out of gas. The gauge said I had about 1/4 tank, but the bottom of my tank was so beat up, that the 15 gal tank really only held about 8 gal. so... this was in order.

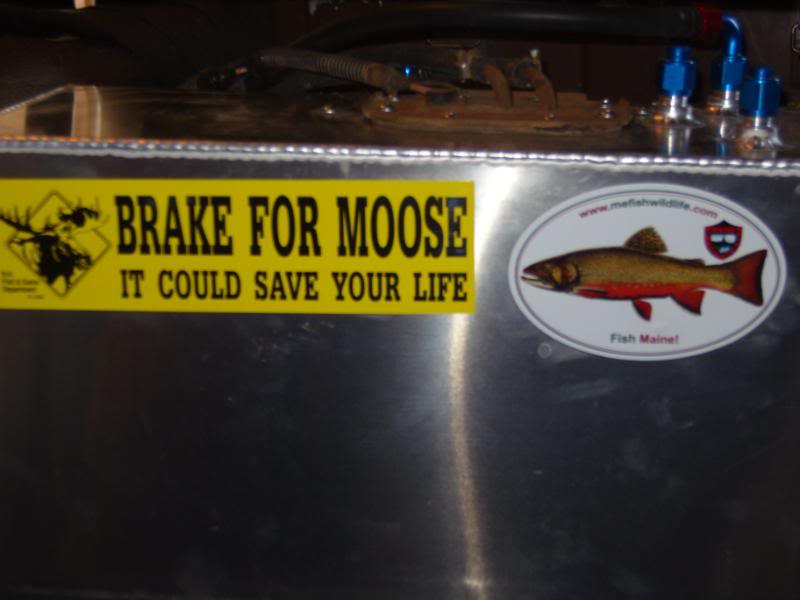

Got me a RCI 2161A fuel cell of ebay for a screaming $150 shipped.

I got the -8 fitting from Summit. not the cheapest way to do it, the cell uses the same 37* taper that Hydraulic lines use and could have just got some at the local hose shop, but these are super bling.

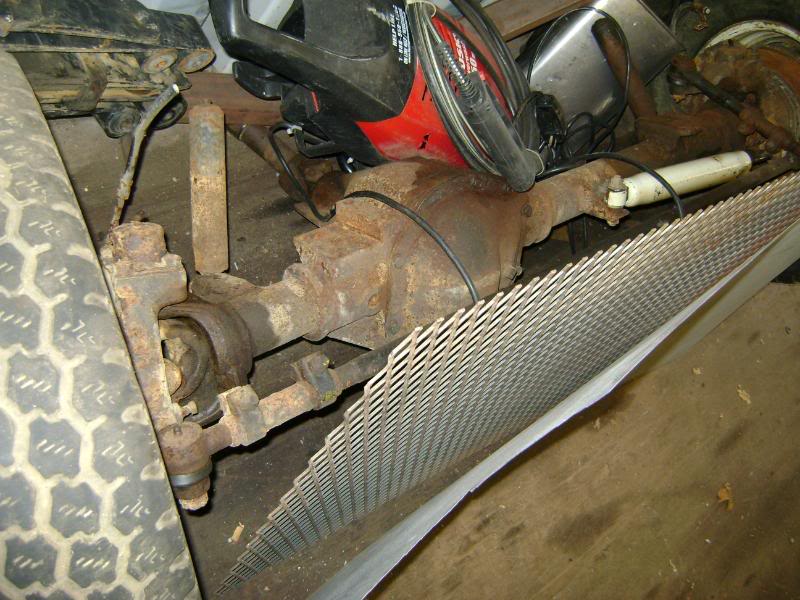

Gonna be stretching to 106†wheel base with a Big ol’ 14 bolt rear, so this had to go, plus last trail ride I ran out of gas and it would only seem like a smart time to do it while it was empty.

What a way to waste a Friday.. Drinking beer and spending 2 hours to take out a out a gas tank that should have only been 30 minutes, but it is out!

Putting in a 2162A RCI tank

Mocked up

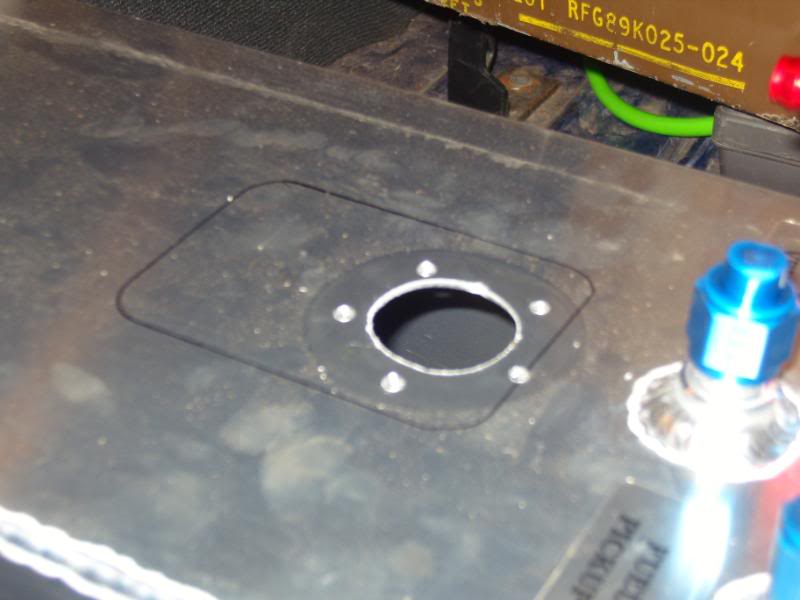

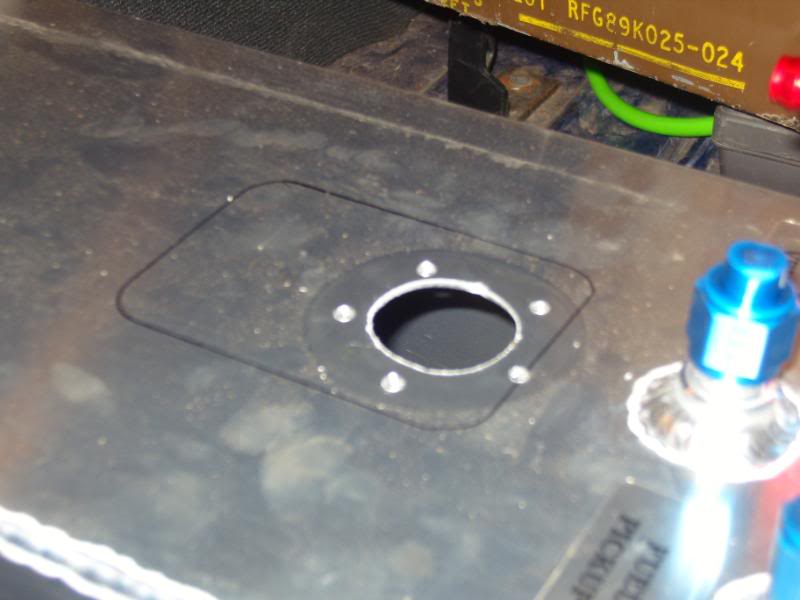

Re-use the factory pump and sending unit, mark for the cut

Thanks to a friend in the Jeep business for hooking my up with a junk Fuel plate flange, allowed me to make my retainer flange for the fuel cell with out actually having to pull mine out. Really made the installation move along quicker.

Tig welded up the original float assembally. I want to keep using the stock fuel gauge, so I would re-use the stock sender, but the float hit the side of the cell and needed to be shortened by about 1.5â€

Tossed it in, fit like a glove

I will eventually sink the cell down through the body and in between the frame rails, but dues to lack of time, and desire to wheel it, this will have to do for now. So I found these poly swap bar end link bushings at auto zone.

Here is what I did with them, real nice vibration isolators if I do say so myself.

While I was at a local marine store buying these for my hood (pics to come on this)

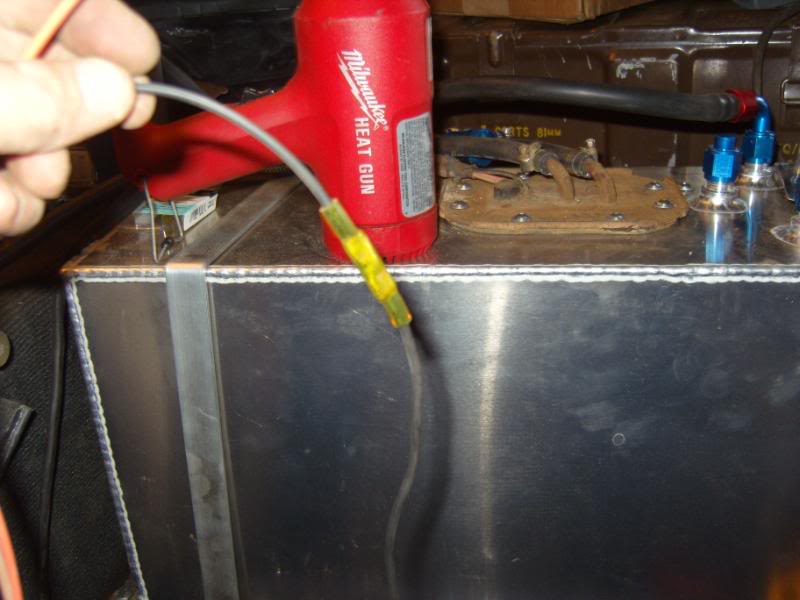

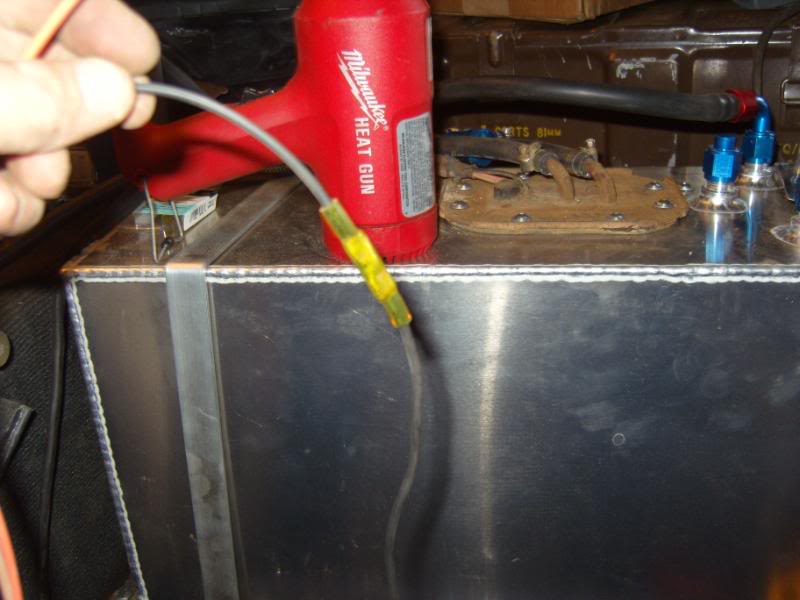

I bought heat shrink water proof connectors and re-wired the fuel pump, replumbed the pump, while at west I also found a 3/8-1/4 plastic barbed hose bushing (you can kind see it in the third pic, it is white), I was going to run the vent up to the under hood area, I made a little splash guard for it and stuff, but now I will simply reuse the stock charcoal canister.

Finished her up just right

JK guys, you all need to start somewhere.

Well.. I am in the last stages of stretching teh wheel base in my 94 YJ to 106", that's moving the front axle forward about 5.5" and pulling the rear back about 5.5"

On the last trail ride I went on a couple weeks ago, I ran out of gas. The gauge said I had about 1/4 tank, but the bottom of my tank was so beat up, that the 15 gal tank really only held about 8 gal. so... this was in order.

Got me a RCI 2161A fuel cell of ebay for a screaming $150 shipped.

I got the -8 fitting from Summit. not the cheapest way to do it, the cell uses the same 37* taper that Hydraulic lines use and could have just got some at the local hose shop, but these are super bling.

Gonna be stretching to 106†wheel base with a Big ol’ 14 bolt rear, so this had to go, plus last trail ride I ran out of gas and it would only seem like a smart time to do it while it was empty.

What a way to waste a Friday.. Drinking beer and spending 2 hours to take out a out a gas tank that should have only been 30 minutes, but it is out!

Putting in a 2162A RCI tank

Mocked up

Re-use the factory pump and sending unit, mark for the cut

Thanks to a friend in the Jeep business for hooking my up with a junk Fuel plate flange, allowed me to make my retainer flange for the fuel cell with out actually having to pull mine out. Really made the installation move along quicker.

Tig welded up the original float assembally. I want to keep using the stock fuel gauge, so I would re-use the stock sender, but the float hit the side of the cell and needed to be shortened by about 1.5â€

Tossed it in, fit like a glove

I will eventually sink the cell down through the body and in between the frame rails, but dues to lack of time, and desire to wheel it, this will have to do for now. So I found these poly swap bar end link bushings at auto zone.

Here is what I did with them, real nice vibration isolators if I do say so myself.

While I was at a local marine store buying these for my hood (pics to come on this)

I bought heat shrink water proof connectors and re-wired the fuel pump, replumbed the pump, while at west I also found a 3/8-1/4 plastic barbed hose bushing (you can kind see it in the third pic, it is white), I was going to run the vent up to the under hood area, I made a little splash guard for it and stuff, but now I will simply reuse the stock charcoal canister.

Finished her up just right