You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

piston ring problem

- Thread starter sweetpeet

- Start date

SteelHeadz

Super Moderator

That's pretty common. Avoid spreading the rings anymore than you have to when installing them. Make sure the gaps on the rings are opposing each other before you install them in the cylinder. That goes both for the oil rings and the compression rings.

bobcat481

New member

By ring gap, in mean that when the rings are inserted into the bore, without being on the piston, there should be a gap where the two ends meet. Slide them into the bore, and "square" them up in the bore by sliding a piston down to them. When you pull the piston back out, then SHOULD be a gap where the two ends meet. You should find specs on what that gap should be. Then you need to file one end of the ring down to get to the required gap. This gap assures that there is no "bind" when it cycles up and down. I think some rings come "pre-gapped" but checking into it won't hurt any. As far as a notch on the piston itself, I'm not sure about. Maybe someone else has some thoughts. Later

sweetpeet

New member

By ring gap, in mean that when the rings are inserted into the bore, without being on the piston, there should be a gap where the two ends meet. Slide them into the bore, and "square" them up in the bore by sliding a piston down to them. When you pull the piston back out, then SHOULD be a gap where the two ends meet. You should find specs on what that gap should be. Then you need to file one end of the ring down to get to the required gap. This gap assures that there is no "bind" when it cycles up and down. I think some rings come "pre-gapped" but checking into it won't hurt any. As far as a notch on the piston itself, I'm not sure about. Maybe someone else has some thoughts. Later

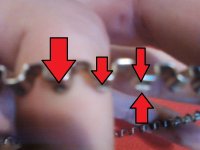

no the notch is not on the piston its on the ring and its keeping my from putting the ring in the slot in the piston. here's a picture.

Attachments

Crazy4diesels

New member

Looks like the "notch" is there to keep the spreader from contacting the cylinder. The two oil rings and the spreader should fit together as a tight sandwich. Try to fit them together off the piston first so you can see how they lock in place. Then get a micrometer measurement of the assembled stack. Then you can measure the piston groove and see if you have the required side clearance. You can do this with a feeler guage too. Just place the assembled stack into the groove "backwards" (so the piston and ring look like a figure 8 from the top) and check the side clearance with feeler guages. Check a few places around the ring and piston. The spreader acts like a spring to keep the oil rings in proper contact with the cylinder. These multi-piece rings are a pain to get in but they do a better job at oil control. Best of luck - John

sweetpeet

New member

Looks like the "notch" is there to keep the spreader from contacting the cylinder. The two oil rings and the spreader should fit together as a tight sandwich. Try to fit them together off the piston first so you can see how they lock in place. Then get a micrometer measurement of the assembled stack. Then you can measure the piston groove and see if you have the required side clearance. You can do this with a feeler guage too. Just place the assembled stack into the groove "backwards" (so the piston and ring look like a figure 8 from the top) and check the side clearance with feeler guages. Check a few places around the ring and piston. The spreader acts like a spring to keep the oil rings in proper contact with the cylinder. These multi-piece rings are a pain to get in but they do a better job at oil control. Best of luck - John

by spreader, do you mean the notch thing that I am talking about? if do is it of for me to shave that off so that it fits?

Crazy4diesels

New member

The spreader is the wavy thing. Two very thin rings and the spreader go together like a sandwich and make up the "oil ring". DO NOT shave off any part of the assembly. The only place you would want to file (if needed) is the end gap (as described by Bobcat). The spreader should lock together with the rings and fit into the piston groove. If it doesn't fit you might have the wrong rings. One more thing... I don't remember for sure on the thin oil rings but they might have an "UP" side. The compression rings probably do have an "UP" side, usually identified by a chamfer along the inner edge. Check your book to see if the chamfer goes up or down (sorry, it's been a long time since I've done this) . Hope this helps... Best of luck - John

sweetpeet

New member

The spreader is the wavy thing. Two very thin rings and the spreader go together like a sandwich and make up the "oil ring". DO NOT shave off any part of the assembly. The only place you would want to file (if needed) is the end gap (as described by Bobcat). The spreader should lock together with the rings and fit into the piston groove. If it doesn't fit you might have the wrong rings. One more thing... I don't remember for sure on the thin oil rings but they might have an "UP" side. The compression rings probably do have an "UP" side, usually identified by a chamfer along the inner edge. Check your book to see if the chamfer goes up or down (sorry, it's been a long time since I've done this) . Hope this helps... Best of luck - John

well then I think the guy gave me the wrong rings in the kit because the the spreader looks identical on both sides and won fit. okay ill have to get the right fitting ones.

Last edited:

Crazy4diesels

New member

How many of the very thin oil rings came in the kit. You should have gotten 8 spreaders and 16 thin oil rings. Two thin oil rings and one spreader go on each piston in the lower groove to form the "three piece oil ring" . So the complete kit should have 16 thick compression rings, 16 thin oil rings, and 8 spreaders. Also, while checking to see if they got you the right rings... have them make sure the pistons are made for three piece oil rings. Some engines use a one piece oil ring with drilled holes in the edge. Does your manual show any good sketches of the assembly? Best of luck - John

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 1

- Views

- 10K

- Replies

- 0

- Views

- 7K