You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this pinion as bad as I think it is?

- Thread starter TerryMason

- Start date

JPNinPA

Well-known member

Yep. Thats your pinion opinion.Okay got the opinion out. It didn't take much effort for my impact to pull off that pinion nut.

To my untrained eye, the pinion gear itself looks good but the bearing and races looks cooked

Sent from my Pixel 7 using Tapatalk

Never look down on anyone unless you are helping them up - Jesse Jackson

Things were going good today for a while, I had my backlash dialed into 10,000s and everything looked good. I decided to run a pattern before I buttoned everything up. From what I gather this is a pretty bad pattern. I applied way too much of the paint but the drive side looks pretty bad.

I'm not sure if I need to change the backlash by removing carrier shims or if I need to change the pinion shim. I'm open to any ideas.

Sent from my Pixel 7 using Tapatalk

I'm not sure if I need to change the backlash by removing carrier shims or if I need to change the pinion shim. I'm open to any ideas.

Sent from my Pixel 7 using Tapatalk

I'm trying to decide if it this scenario is the green or the blue.

I tried to shortcut things, and just went full send with a crush sleeve, locktite, etc. I assumed that since I was just changing the two pinion bearing and races I'd be fine. Now I need to pull it apart.

I'll try moving the carrier shims first, and if that doesn't change things the I'll pull the pinion gear out and change it's shims.

I tried to shortcut things, and just went full send with a crush sleeve, locktite, etc. I assumed that since I was just changing the two pinion bearing and races I'd be fine. Now I need to pull it apart.

I'll try moving the carrier shims first, and if that doesn't change things the I'll pull the pinion gear out and change it's shims.

I'm still plugging away at this. Definitely learning a lot from this process.

I think I've got the carrier shims dialed in and I'm clocking about 9 thousands of backlash which is good.

I went ahead and made set up bearings which entails hollowing out the same brand Pinion bearing that I will eventually use. That way I can change the pinion shim without having to press on and ruin the bearing every time.

I think my latest set of marks indicate that I still need a thinner pinion shim.

Sent from my Pixel 7 using Tapatalk

I think I've got the carrier shims dialed in and I'm clocking about 9 thousands of backlash which is good.

I went ahead and made set up bearings which entails hollowing out the same brand Pinion bearing that I will eventually use. That way I can change the pinion shim without having to press on and ruin the bearing every time.

I think my latest set of marks indicate that I still need a thinner pinion shim.

Sent from my Pixel 7 using Tapatalk

This is what I'm getting with a 0.010 inch pinion shim

Coast side

And drive side

Leaving this here mainly so I can keep track of which shims look best

Sent from my Pixel 7 using Tapatalk

Coast side

And drive side

Leaving this here mainly so I can keep track of which shims look best

Sent from my Pixel 7 using Tapatalk

0.012 inch pinion shim

Coast side

Drive side

Sent from my Pixel 7 using Tapatalk

Coast side

Drive side

Sent from my Pixel 7 using Tapatalk

Pinion shim of 0.023 (this was the factory shim)

This much of a change ended up changing my backlash to about 0.05, and it should be between 8 and 12. I ran the patterns anyway just to see what they look like

Drive side

And Coast side

Sent from my Pixel 7 using Tapatalk

This much of a change ended up changing my backlash to about 0.05, and it should be between 8 and 12. I ran the patterns anyway just to see what they look like

Drive side

And Coast side

Sent from my Pixel 7 using Tapatalk

Last edited:

Pinion shims of 0.030

This gave me zero backlash which will have to be fixed, but I think the patterns look better overall.

Coast side

And drive side

Sent from my Pixel 7 using Tapatalk

This gave me zero backlash which will have to be fixed, but I think the patterns look better overall.

Coast side

And drive side

Sent from my Pixel 7 using Tapatalk

JPNinPA

Well-known member

If i interpret the pattern diagram the left side marked drive side has the center of the ring gear to the right and outer to the left. You are looking at the pattern of the retrograde angle or backside of the teeth.

In the diagram right side marked coast side, the center of the ring is to the left and outer to the right. Here you are looking at the sloped side of the teeth.

Being the top row of the chart is desired. The marks should be centered and somewhat rectangular.

If correct 0.010 and 0.012 are like row 4.

0.23 looks close

0.30 looks like row 3

Again im no expert. Have you considered reaching out to currie enterprise?? They may be able to provide sound advice maybe even face-time or teams to review your pics…

Never look down on anyone unless you are helping them up - Jesse Jackson

In the diagram right side marked coast side, the center of the ring is to the left and outer to the right. Here you are looking at the sloped side of the teeth.

Being the top row of the chart is desired. The marks should be centered and somewhat rectangular.

If correct 0.010 and 0.012 are like row 4.

0.23 looks close

0.30 looks like row 3

Again im no expert. Have you considered reaching out to currie enterprise?? They may be able to provide sound advice maybe even face-time or teams to review your pics…

Never look down on anyone unless you are helping them up - Jesse Jackson

I'll agree that 23 looked good, but only on the coast side. From what I read, I should focus on the drive side primarily.

I think I'm on the right track now. This time around I kept the 0.030 pinion, but went back to the factory carrier shims. These are way too loose and my backlash was only five, but I think the pattern is on the right track now.

Now I think I'll play around with the carrier shims, adding a bit more on the left / driver in order to increase the backlash.

Pinion shims : 0.030

Coast side

Drive side

Sent from my Pixel 7 using Tapatalk

I think I'm on the right track now. This time around I kept the 0.030 pinion, but went back to the factory carrier shims. These are way too loose and my backlash was only five, but I think the pattern is on the right track now.

Now I think I'll play around with the carrier shims, adding a bit more on the left / driver in order to increase the backlash.

Pinion shims : 0.030

Coast side

Drive side

Sent from my Pixel 7 using Tapatalk

Last edited:

I finally got it all wrapped up! I am by no means good at this, but I ended up taking the carrier / pinion out at least 25 times - one one Saturday I had the whole thing apart and together at least seven times.

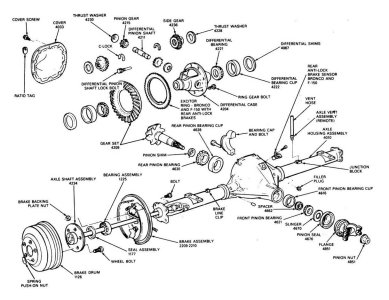

I believe my core problem was that the pinion bearing became worn. This allowed play in the pinion gear itself, and poor engagement with the ring gear. As I noticed earlier in this thread, there was no backlash in the pinion at all, and it would flop around by hand.

The "fix" for me was to replace the pinion bearings and races, then choose the proper pinion shims and carrier shims - reusing my factory gears. In my case the pinion shim needed to be reduced from what the factory was - I think I went from 0.023 to 0.012"

Things I learned along the way:

At the end of the day, it's not really that difficult. It's intimidating, but I took my time and did it dozens of times until I got pretty good at setting things up. I've got over 125 miles on it, including quite a bit if highway, and it is sooooo much quieter now.

Great videos to watch:

I believe my core problem was that the pinion bearing became worn. This allowed play in the pinion gear itself, and poor engagement with the ring gear. As I noticed earlier in this thread, there was no backlash in the pinion at all, and it would flop around by hand.

The "fix" for me was to replace the pinion bearings and races, then choose the proper pinion shims and carrier shims - reusing my factory gears. In my case the pinion shim needed to be reduced from what the factory was - I think I went from 0.023 to 0.012"

Things I learned along the way:

- You have to make a setup bearing for the pinion gear. Order two of the same bearings (i.e. same manufacturer) and use a die grinder to expand one so that it slips over the pinion easily. You'll use this to change the pinion shims over and over again.

- Get the pinion shim / depth correct before worrying about the carrier shims. This is a bit hard to do as you need to read the gear patterns along the way, but focus on pinion shims first.

- mix gear oil into the gear paint. I think I was putting 3/4 gear oil to 1/4 paint. This make the paint go on better, and makes the patterns much easier to read. When I was using the paint straight I could barely see what was going on yellow everywhere!

- drive side patterns are way more important than coast side. Get the drive side as good as possible and run it.

- with used gears (like I was doing), you may never get a perfect pattern. In an ideal world, you would want to get the pattern back to the way it was from the factory, since these are "mated gears". No possible in my situation. I agonized over the pattern, and got a pretty good one, but not as good as the ones you see in the videos.

At the end of the day, it's not really that difficult. It's intimidating, but I took my time and did it dozens of times until I got pretty good at setting things up. I've got over 125 miles on it, including quite a bit if highway, and it is sooooo much quieter now.

Great videos to watch:

Last edited:

Similar threads

- Replies

- 1

- Views

- 10K

- Replies

- 1

- Views

- 34K

- Replies

- 7

- Views

- 4K