JeepsterCJ5

New member

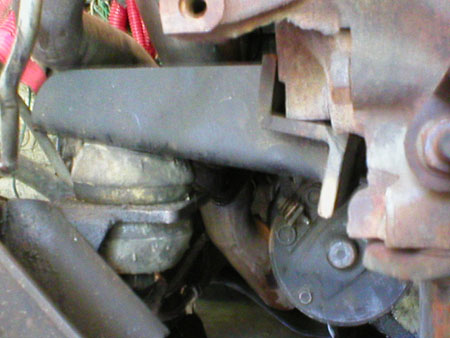

I'm thinking of doing a conversion to the smallblock Ford. Does anyone have any experience with this?

It would be in my 1978 CJ5 has a 304 with a t-150 dana 20 transfer

any ideas from the more experienced Jeepers?

It would be in my 1978 CJ5 has a 304 with a t-150 dana 20 transfer

any ideas from the more experienced Jeepers?